.

– 2008 Detroit Auto Show Audi R8 V12 TDi konsept modelinin 12 silindirli yüksek torklu dizel spor aracın tanıtımı yapıldı. Yeni geliştirilen Dizel Güç ünitesi, zerafeti simgeleyen gri rengi, fantastik dizaynı ve öncülük eden teknolojisi ile karşımızda.

– Audi, Le-Mans tecrübelerini gerçek yol koşullarında denemek için R8 V12 TDi modeline aktardı.Audi R10 (yeni motora en yakın özelliklere sahip), 24 saatlik Le-Mans yarışlarını 2006 ve 2007 yıllarında toplamda 2 kere kazandı. Geçen sene Q7 Konseptinde kullanılan 6.0L V-12 dizel motoru, ödül kazanan R8 spor aracına yerleştirdi. Birçok yarış kazanan R10 motorundan, yeni konsept motorun 2 silindir fazlalığı var. R10 motoru 650Hp, 5.5L, vites oranlarıyla oynanarak 330 km/h (205.05 mph) son hıza sahip.

– Audi’nin mevcut motor ailesinde 6-8 silindirli FSi benzinli ve TDi dizel motorlar bulunmakta. Bu sayede diğer otomobil şirketlerine gizliden ne kadar güçlü olduğunu göstermeye çalışıyor. Yeni motorda 60 derecelik açıyla karşılıklı yerleştirilmiş silindirler var iken yarış versiyonu olan motorda 90 derecelik bloklar kullanılmış.

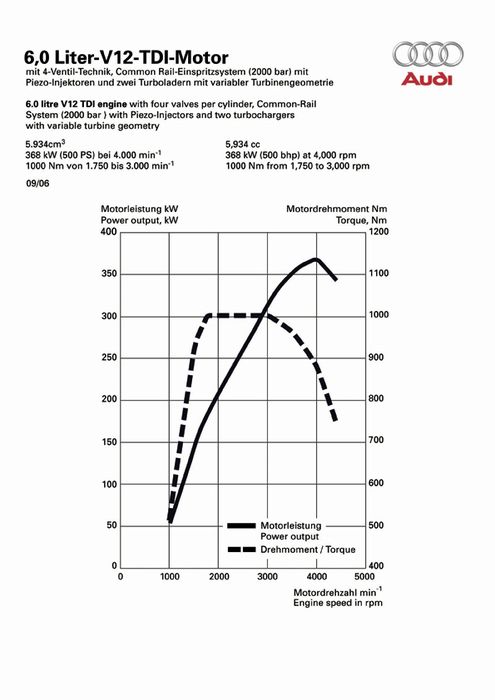

– 500HP (368 kW) motor gücü, 738 lb-ft (1000NM) tork, 4 tekerlek üzerine rahatça aktarılıyor.R8 V12 TDI, rüzgar gibide hızlı. 0-100km (62.14 mph) hıza 4.2sn, son hızı 300 km/h (186.41 mph), maksimum torkunu 1,750 rpm veren ve tüketimi 23 MPG.

.

– 83.0 mm (3.27 in.) çapında, 91.4 mm (3.60 in.) strok ile toplam: 5,934 cc hacme sahip motor, Audinin 3.0 TDi modeliyle benzerlik gösteriyor. V8 TDi motordan, 166 mm (6.54 in.) daha uzun (Gerçek uzunluğu: 684 mm (26.93 in.)) yapısıyla kompakt bir yapıda olduğunu kanıtlıyor. Krank yapım malzemesi: “The V12 TDI crankcase is made from gray cast iron with vermicular graphite – a high-tech material referred to as GJV-450 that is already used on the V6 and V8 TDI engines. GJV-450, made by a patented casting process, is about 40 percent more rigid and 100 percent more fatigue-resistant than gray cast iron. This enabled the developers to make its walls thinner, cutting its weight by around 15 percent compared with conventional gray cast iron.” Yanlış çevirmek istemedim o yüzden ingilizcesini aktardım. Normal gir metale göre daha dayanıklı, uzun ömürlü olduğu söyleniyor. Silindir kafaları 3 ana elemntten imal edilmiş. Yüksek çekme dayanımına sahip alüminyum malzeme, egzoz portlarında, 2 tane kam milinde yağ pompalama birimlerinde kullanılmış.

– Komprasyon oranı: 16.0:1. Yüksek teknoloji yeni yakıt sistemi, Bosch tarafından hazırlanmış Piezzo enjektörlerde boru basıncı 2,000 bar.(Piezzo aslında enjektörde kullanılan elektrikle yüklenen seramik parçacıkların adı.) Direkt enjeksiyonlu yakıt pompasının toplam basıncı 29,000-psi, partikül filtresi ve üre enjeksiyonu ilede 2014 Euro VI normalarını fazlasıyla karşılamakta. Yakıtın en iy şekilde homojen – artıksız yanmasını sağlamakta. Bunu yapmak için gerekirse 5 adete kadar püskürtme işlemi gerçekleştiriyor. V motor yapısında 2 adet turboşarj ünitesi bulunuyor. 2.6bar‘ı bulan itme basıncı ile 1000Nm’lik torku 1,750 rpm ile 3000 rpm aralığında ayağımızın altına seriyor. Litre başına düzen güç ise 62.0 kW (84.3 hp).

-2 adet dev intercoolera sahip motor emdiği yüksek sıcaklıktaki havayı soğutuyor. 2 adet partikül filtresi ile temizlediği gazı Çift egzoz çıkışı sayesinde güzel atmosferimize gönderiyor. Motor, 2014 yılında normlara ve yakıt kalitesine uygun hazırlandığı için Audi mühendisleri şu anki koşullara uygun olması için çalışıyor. Partikül filtresi 2 kompenentten oluşmakta. Birincisi partikül filtreleri ve bunun hemen üzerinde yer alan üre tankı. Bu tanktaki üre egzoz gazının partikül filtresi içersinden geçerken üzerine bırakılarak zararlı atıkların yok edilmesini sağlıyor. Nitrojen oksidi , nitrojen ve suya dönüştürüyor. Buna bir isimde bulmuşlar “ADBlue“. Bildiğimiz gibi Mercedeste benzer işlemi yapan sistemi “Blue Tech” olarak duyurmuştu ve motorlarının isminide Bluetech motor diye adlandırıp satmaya başlamıştı. (Amerikada satılıyor diye biliyorum.) Bu kadar yüksek torka sahip motor için özel 6 ileri vitesli manuel vites kutusu hazırlanmış. tabiyki yüksek performans odaklı. Çift diskli kavrama sistemi kullanılan ve alüminyumdan imal edilmiş. Motor iki aks arasına konumlandırılmış ve aracın ağırlık dağılımı 40:60. Buda ön ve arka tekerleklere hem güç dağılımını hemde aktarımın kolay yapılabilmesini sağlamış.

Outstanding Torque for the Top Class

Audi R8 V12 TDI conceptAudi is presenting a revolution in the top class at the Detroit Auto Show 2008 – the first 12-cylinder diesel engine in a high-performance roadgoing sports car. The V12 TDI with a displacement of six liters powers a concept car based on the Audi R8. This unit generates a huge 500 hp and 1,000 Newton-meters (737.56 lb-ft) of torque. Audi is writing a new chapter in diesel technology with this power unit. Equipped with the expertise that Audi has built up through its motor sport activities, the R8 V12 TDI in matt “Grace Silver” embodies superb road handling, pioneering technology and fascinating design.

The V12 TDI is closely related to the engine in the Audi R10, the two-time

Le Mans winner – so it catapults the Audi R8 into supercar terrain concerning performance too. It sprints from zero to 100 km/h (62.14 mph) in just 4.2 seconds and its top speed is well over 300 km/h (186.41 mph). The peak torque, reached at only 1,750 rpm, paves the way for effortless acceleration that is unrivaled even at this level.The new V12 TDI belongs to Audi’s family of V engines but has the ideal included angle for this engine type of 60 degrees between cylinder banks. Its highlights include the new chain drive layout that includes the two newly developed high-pressure pumps for the common rail injection system.

Its sound is as thrilling as you’d expect in a sports car of this caliber. For all the subtle smoothness that typifies this design principle, the twelve-cylinder unit is full-bodied and equipped with energetic overtones that make no secret of its performance potential.

The Genes of the Winner

Thanks to their high performance and pulling power, all Audi TDI engines are ultra-dynamic sources of power. The brand has often enough demonstrated its sporty character in its production cars, especially the six- and eight-cylinder

3.0 TDI and 4.2 TDI. Audi has also been writing a new chapter in its success story on the racetrack since 2006. The diesel engine in the R10 sports prototype won its very first endurance race at Sebring, Florida, when it was pitted against an entire field of gasoline-engined challengers. But its most crucial victories were surely in 2006 and 2007 in the 24 Hours of Le Mans, when it simply outclassed the international elite.The V12 TDI race engine in the R10 produces over 650 hp from a displacement of 5.5 liters, giving it the potential for a top speed as high as 330 km/h

(205.05 mph) depending on the gear ratios. Its power and sturdiness immediately impressed both fans and experts, who were impressed by its restrained noise level. Unusual for a race engine, this powerful Audi diesel makes barely more than a whisper.Long traditions of motor racing and production technology complement each other at Audi. The FSI engine of the R10’s predecessor, the R8, captured five wins at Le Mans with a direct gasoline injection system. Audi is also looking to maximize the advantage by using the race-tested FSI principle in its production models. The latest examples of this are the V8 with high-revving concept in the RS 4 and the production version of the Audi R8.

The Drivetrain

The roadgoing version of the new V12 TDI is built at the Györ plant, in Hungary. And the R8 V12 TDI still has a massive 500 hp on tap. In developing the six-liter engine, it was a clear priority to integrate it into the current family of Audi V engines, of which many thousands of versions with 6, 8 and 10 cylinders have already been built – both gasoline and TDI.

Audi’s engineers were in an ideal position to use their experience building the racing engine to develop the road version. Like the other power units in this range, the distance between cylinder bore axes on the V12 TDI is 90 mm (3.54 in.). Yet its included angle is 60 degrees, not 90 degrees. This means no free inertial forces or mass moments of inertia can occur with the V12. The results are refined in every respect.

The 83.0 mm (3.27 in.) bore and 91.4 mm (3.60 in.) stroke produce a total displacement of 5,934 cc – just like the 3.0 TDI. At only 684 mm (26.93 in.) long, this large diesel engine is very compact and just 166 mm (6.54 in.) longer than the V8 TDI. This compact length is key to accommodating the V12 in the mid-engined Audi R8.

The V12 TDI crankcase is made from gray cast iron with vermicular graphite – a high-tech material referred to as GJV-450 that is already used on the V6 and V8 TDI engines. GJV-450, made by a patented casting process, is about 40 percent more rigid and 100 percent more fatigue-resistant than gray cast iron. This enabled the developers to make its walls thinner, cutting its weight by around

15 percent compared with conventional gray cast iron.The two cylinder heads are each made from three main elements. These are a base section made from a high-strength aluminum alloy incorporating the intake and exhaust ports, an oil-bearing upper section, and a reinforcing ladder frame supporting the two camshafts.

The valves are actuated by low-friction roller cam followers; the compression ratio is 16.0:1. Map-controlled swirl variation of the combustion air has been adopted from the V6 and V8 TDI engines. This produces permanently optimized swirl concerning both emissions and high performance.

Ultramodern Injection Technology

As is the case in the Audi V engines, the no-maintenance chain drive is mounted at the back of the engine, where it occupies little space. Its layout has changed on the new V12 TDI. The camshafts’ sprocket engages in an intermediate gear via which two Simplex chains drive the camshafts. Two more chains drive the oil pump and the two high-pressure pumps actuate the common rail injection system.

The two new dual-piston high-pressure pumps form part of the common rail injection system supplied by specialty manufacturer Bosch. The two pumps build up a pressure of up to 2,000 bar in the rails. The piezo injectors with eight-hole nozzles have also been fundamentally revised.

The high pressure distributes the mixture optimally throughout the combustion chamber. The result is that the ignition process is faster, more homogeneous and more acoustically refined. The more efficient combustion process also increases power output, cuts consumption and reduces pollutant emissions.

The current generation of so-called inline injectors makes effective use of the piezo effect: piezo crystals expand in a fraction of a millisecond when an electrical voltage is applied. The number of injection processes per operating cycle can be varied across a wide range thanks to piezo technology – reaching as many as five fuel injection operations in the case of the V12 TDI.

As well as the main injection, pilot and post injections are possible. Pilot injections tone down the acoustic harshness of the combustion process. Retarded post injections are designed specifically to increase the temperature of the exhaust gas, promoting regeneration of the two standard particulate filters.

The two turbochargers are located on the outside of the engine’s V, each of them supplying one bank of cylinders. Thanks to their variable turbine geometry, the full flow of exhaust gas always passes through the turbine, so the chargers respond slickly – even at low engine speeds – and operate very efficiently.

The two turbochargers, which generate up to 2.6 bar of boost pressure, play a crucial role in producing the huge torque of 1,000 Nm (737.56 lb-ft) that the

V12 TDI maintains from 1,750 rpm to 3,000 rpm. In developing 368 kW

(500 hp), the diesel achieves a specific output of 62.0 kW (84.3 hp) per liter displacement.Two large intercoolers reduce the temperature of the compressed air. The V12 has a twin-pipe exhaust system with two particulate filters. The intake system is similar in structure with one air cleaner per cylinder bank, with an airflow meter behind it. Two control units, sharing the workload in a master/slave principle, manage events in the engine.

The Audi R8 V12 TDI concept already fulfills the Euro 6 emissions standard that is likely to take effect in 2014 and calls for sharply reduced nitrogen oxides. By also designing in ultra-precise fuel metering by the common rail system, Audi’s engineers have made full use of current clean diesel technology.

The heart of the system is a special catalytic converter downstream of the oxidizing catalyst and the particulate filter. The second component in the system is an additional tank containing an aqueous urea solution. Small quantities of the solution, known as “AdBlue,” are injected into the exhaust system. The hot exhaust gases break the solution down to form ammonia that splits the nitric oxides into nitrogen and water. The system remains effective for the entire service life of the vehicle.

The dynamic character of a sports car depends not just on its performance and torque; the transmission ratios have to be right too. In keeping with the character of a high-performance sports car with unbeatable torque potential, the transmission in the R8 V12 TDI has six manually operated gears.

The manual transmission is very compact in design. Together with the small-diameter double-plate clutch, this means it can be installed low down. The manual transmission has very short shift travel and utterly precise guiding of the shifter into the open gear lever gate. It is made from polished aluminum, has an agreeable feel and exquisite sports car looks.

Such a high-performance Audi also has quattro permanent all-wheel drive. In the case of this mid-engine sports car, power is distributed variably between the front and rear wheels from a starting ratio of 40:60 to optimize the handling.

Diesel Milestones from Audi

Audi has reached another milestone in diesel technology with the new V12 TDI. The brand with the four rings has been performing vital pioneering work in this area for the past three decades. Audi premiered the world’s first five-cylinder diesel engine in the Audi 100 in 1978. The first TDI auto engine made its debut in 1989 in the successor model. The 2.5 liter five-cylinder power unit developed 88 kW (120 hp) and 261 Nm, catapulting diesel driving into an entirely new dimension.

This was followed in 1994 by a development version generating 103 kW (140 hp). This engine was optionally available with all-wheel drive – the first TDI quattro model. A new four-cylinder diesel appeared at that time in the Audi 100 and Audi 80, the 1.9 TDI developing 66 kW (90 hp) that has now become legendary.

At the end of 1995 the output of this four-cylinder unit rose to 85 kW (115 hp) with the advent of pump-injector fuel injection. Slightly more than one year later, at the start of 1997, the world’s first 2.5 V6 TDI appeared.

With four valves per cylinder, it achieved an output of 110 kW (150 hp), and its top speed of 220 km/h (136.70 mph) made the Audi A8 the fastest production diesel on the market. The first eight-cylinder TDI followed in 1999 – a V8 engine with a 3.3 liter capacity. The 3.0 TDI made its debut early in 2004 as the first V6 diesel with inline piezo injectors in the common rail system.

The 4.2 liter TDI launched in the A8 in 2005 is currently at the vanguard of Audi’s TDI range. One in three A8 buyers in Germany chose this V8 engine. The next logical step was to make the V8 TDI available in the Audi Q7 in summer 2007.

– Bende dün gece boşluktan yararlanıp kendim içim 3 adet farklı duvarkağıdı yaptım. Sizlerle paylaşıyorum.

Boyutları 1280X1024px olarak kendim için hazırladım. Güle güle kullanın….

.

Kaynak:

http://www.autoblog.com/2008/01/13/detroit-2008-audi-unleashes-its-diesel-monster-the-r8-v12-tdi/

http://www.autobloggreen.com/2008/01/13/detroit-2008-officially-official-audi-r8-v12-tdi-concept/

http://www.worldcarfans.com/9080113.014/audi-r8-v12-tdi-concept-revealed

http://www.audi.de/audi/de/de2/erlebniswelt/design_studien/audi_r8_v12_tdi_concept.html

Pingback: 2008 Audi R8 Wall Paper | Audi Photos Blog